We can customize various types of steel pipes according to customer requirements.

Seamless Steel Pipe Details for references

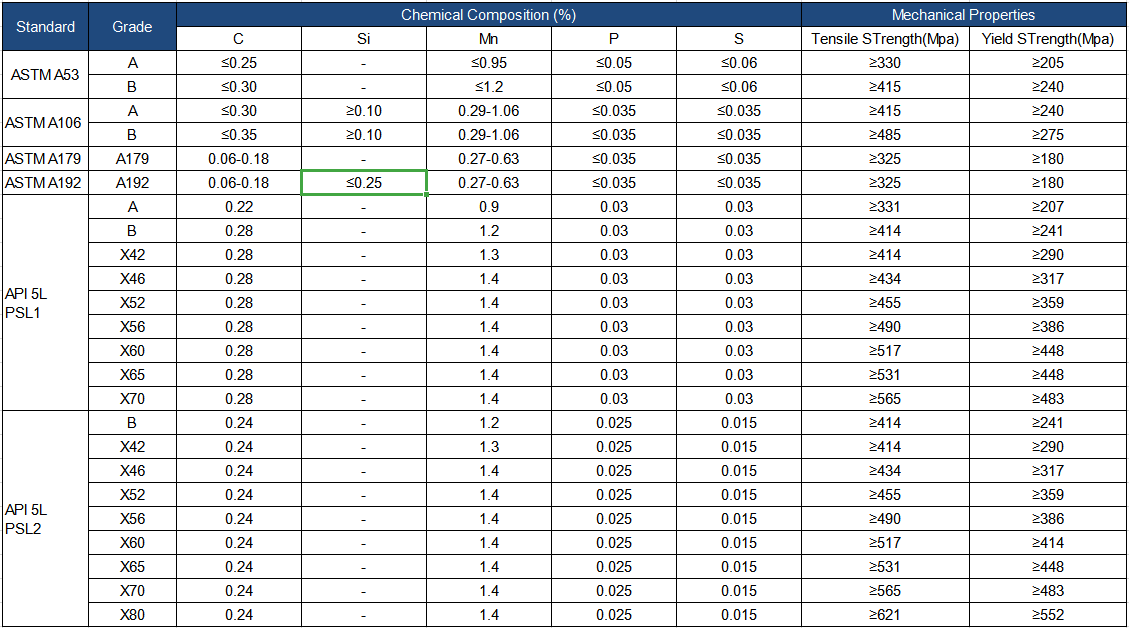

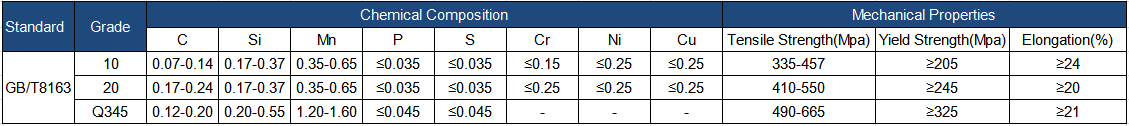

Chemical Composition and Mechanical Properties:

This data is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

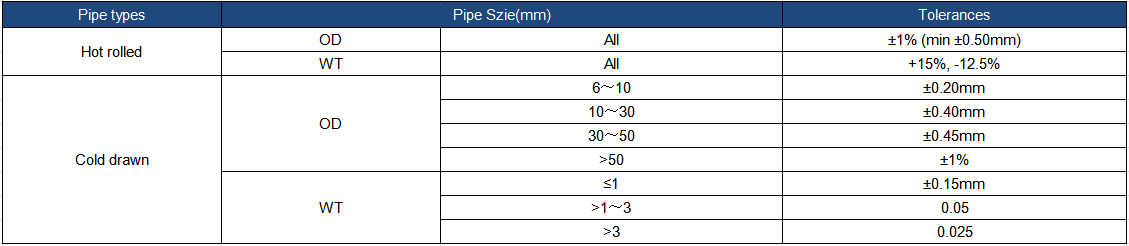

Tolerance of Seamless Steel Pipe:

Need Weled Steel Tube? Click here to view.

Based on production methods, seamless steel pipes can be classified into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and jacketed pipes.

Depending on their cross-sectional shapes, seamless steel tube can be circular or irregular, with irregular pipes including carbon steel square tube, oval steel tube, triangular tube, hexagonal, melon seed-shaped, star-shaped, and winged pipe shapes.

Typically, the maximum diameter can reach 900mm, and the minimum diameter is 4mm.

Depending on their applications, there are thick-wall seamless steel pipes and thin-wall seamless steel pipes.

Seamless steel pipes are mainly used as oil geological drilling pipes, cracking pipes for petrochemical applications, boiler tubes, bearing tubes, as well as high-precision structural steel pipes for automobiles, tractors, and aviation.

Seamless steel pipes refer to steel pipes without seams along the perimeter of their cross-sections. Depending on the production methods, they can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, and jacketed pipes, each with their respective technological specifications.

The materials used include ordinary and high-quality carbon structural steel (Q215-A~Q275-A and steel grades 10~50), low alloy steel (09MnV, 16Mn, etc.), alloy steel, stainless and acid-resistant steel, etc.

Professional Advantages of HeGang Steel Group

Our subordinate processing plant is equipped with medium-frequency heating fully automated thermal expansion units, fully automated beveling machines, German imported integrated processing, drying, and painting equipment, streamlined corrosion-resistant processing equipment, and a complete set of streamlined insulation processing equipment. We can process, cut, thermally expand, or cold draw steel pipes based on customer needs, fully satisfying users' customized requirements.

Our company continues to provide users with high-quality and low-cost products, along with post-sales tracking services ranging from 1 to 10 years. We ensure that every user receives a good purchase and usage experience! We ensure that every user can purchase steel pipe products with high cost-effectiveness at a lower price.