HeGang Steel is top PPGI coils manufacturer in China.

We have an advanced coated steel coil production line to provide customers with product supply guarantee, and a professional sales team to provide customers with pre-sales services.

Product Description for HeGang PPGI and PPGL:

Product Advantages for HeGang PPGI coils&PPGL coils:

⑴Excellent weather resistance and corrosion resistance, with high cost-performance advantages, can be applied to the internal walls, external walls, roofs, and other enclosure systems of buildings in conventional environments.

⑵Using advanced coating systems to comprehensively improve coating performance, it has excellent light and color retention and anti-chalking properties. Combined with highly corrosion-resistant substrates, it is more durable than ordinary color-coated plates.

⑶The coating surface does not peel, crack, or chap.

⑷Higher panel flatness, higher color difference control level, and higher whiteness, which is 5% higher than the whiteness of commonly used white ash color.

VIDEO 1:Color Coated Coil Products of HeGang Steel

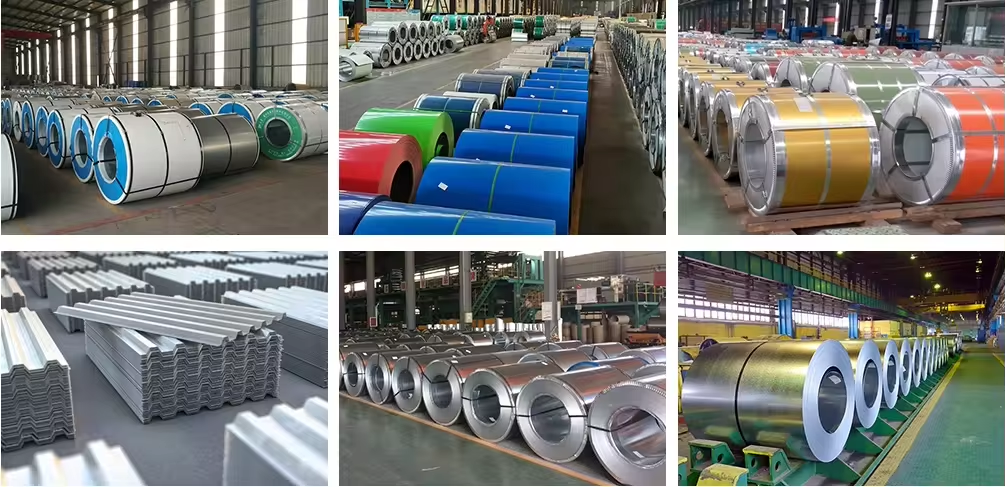

Product show

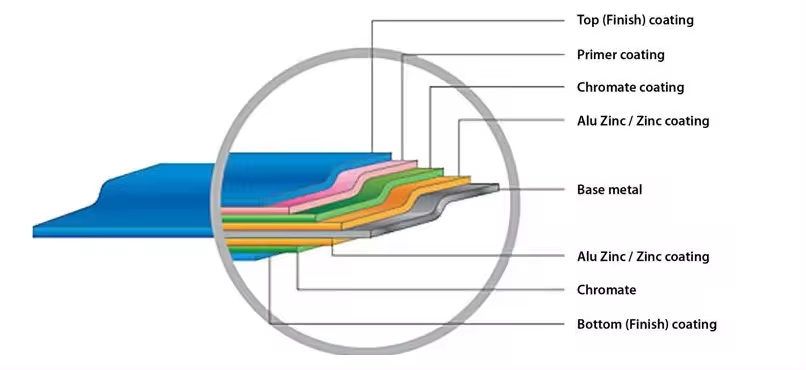

Structure of Prepainted Galvanized Steel Coil:

*Topcoat (finishing) which provides color, pleasing appearance and appearance and a barrier film to enhance long-term durability.

*Primer coat to prevent undercutting of paint and enhance corrosion resistance.

*Pretreatment layer applied for good adhesion and to enhance corrosion resistance.

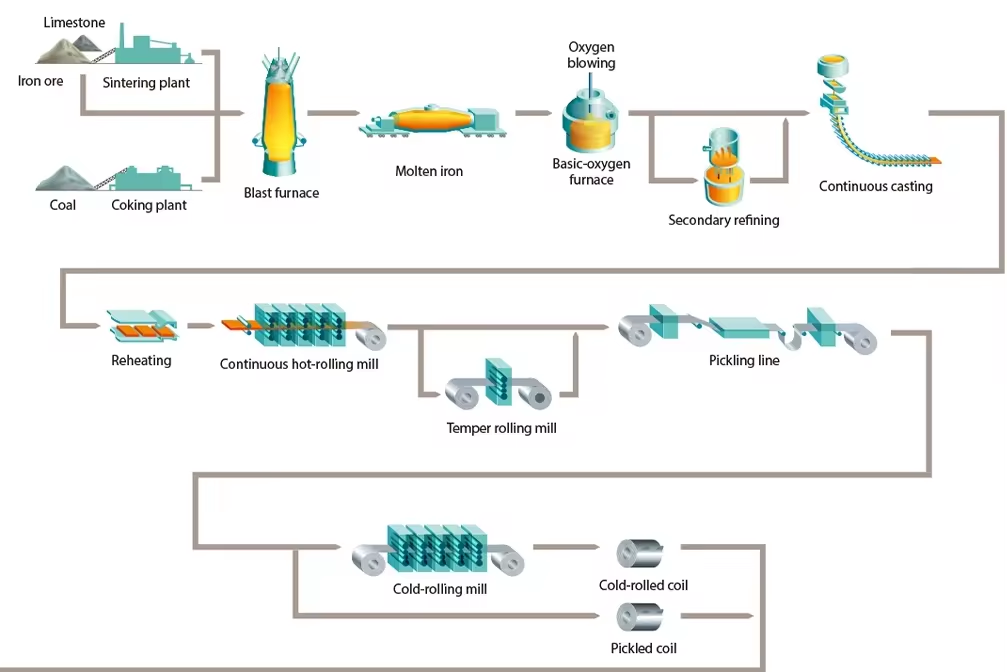

productive process

VIDEO 2:Production Process of Color Coated Coils in Our Factory

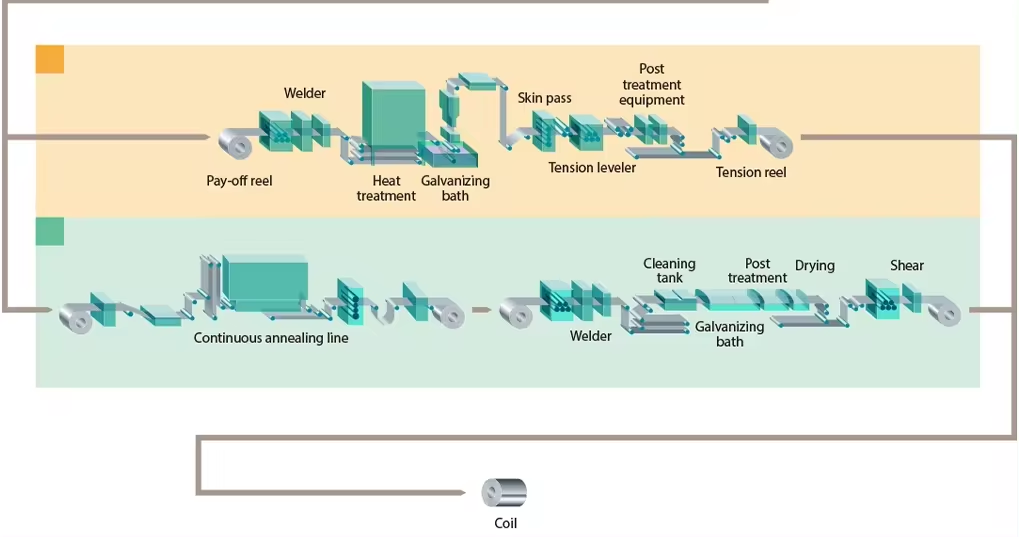

The production method of color coated coil is: on the continuous unit, cold rolled strip steel and galvanized strip steel (electric galvanized and hot dipped galvanized) as the base plate. Color coated coil after surface pretreatment (degreasing, chemical treatment), using the rolling coating method coated with a layer or multiple layers of liquid paint, baking and cooling to obtain the plate for the coating steel plate.

Because the coating can come in a variety of colors, the coated steel plate is usually called color coated steel plate. Because the coating is done before the steel plate is formed and processed, it is also called pre-coated steel plate. The process flow of color coated steel coil is: color coated steel plate is cold-rolled steel plate and galvanized steel plate as the base material, after surface pretreatment (degreasing, cleaning, chemical conversion), continuous coating (rolling coating method), baking, cooling products.

Our Advantages

✔Strict quality control and sufficient inventory

From raw materials to finished products, they have undergone three rounds of quality inspection to ensure that the finished product qualification rate is over 100%. We have a large inventory to provide customers with sufficient supply, allowing customers to avoid the risk of shortage and enabling them to produce and process with confidence.

✔Timely delivery and cost savings

We promise to ship spot products within 3-5 days after customers place orders. For customized products, we will arrange production within 3-5 days according to the product process, and ship the finished products within 7-30 days to meet customers' urgent needs.

✔Comprehensive service and timely response

We have a professional production and research and development team with many years of experience in steel exports. We promise to track each order in time, not only to produce high-quality products for customers but also to ensure that customers can receive their goods safely.

Why choose us?

We have over 20 years of experience in steel plate production, with professional technical personnel and strong capabilities in research and development, design, and production.

We specialize in the production of various types of steel products, such as carbon steel plates, carbon steel coils, steel pipes, section steel, galvanized coils, galvanized plates, and color-coated coils, able to meet customers' various customized needs.

80% of our customers have chosen us due to our strict quality control and good reputation.